Light years behind: Supplier leadership vs people leadership

Let’s face it, we’re light years behind in how we source and manage suppliers. At least in comparison to how we select and lead our staff.

As procurement leaders, our primary concern is on our staff. Staff work our businesses, meet KPIs and protect the bottom line. Hey but so do our suppliers! Why is it that we have little concern about our procurement efforts when up to three quarters in every dollar is reserved for our external suppliers?

Where to start you ask?

In fact we’d argue that the same strategies work across managing people and managing suppliers. At the end of the day we often buy complex services that are heavily dependent on the skills, motivation and environment that the service provider’s staff find on the ground.

This means we can learn to better source and manage our suppliers, if we treat them like our employees!

Lead your suppliers like your staff. Rewarding good behaviour, ensuring that both parties have their interests covered, even simple things like paying on time are all sure ways to better exercise how to better manage your staff.

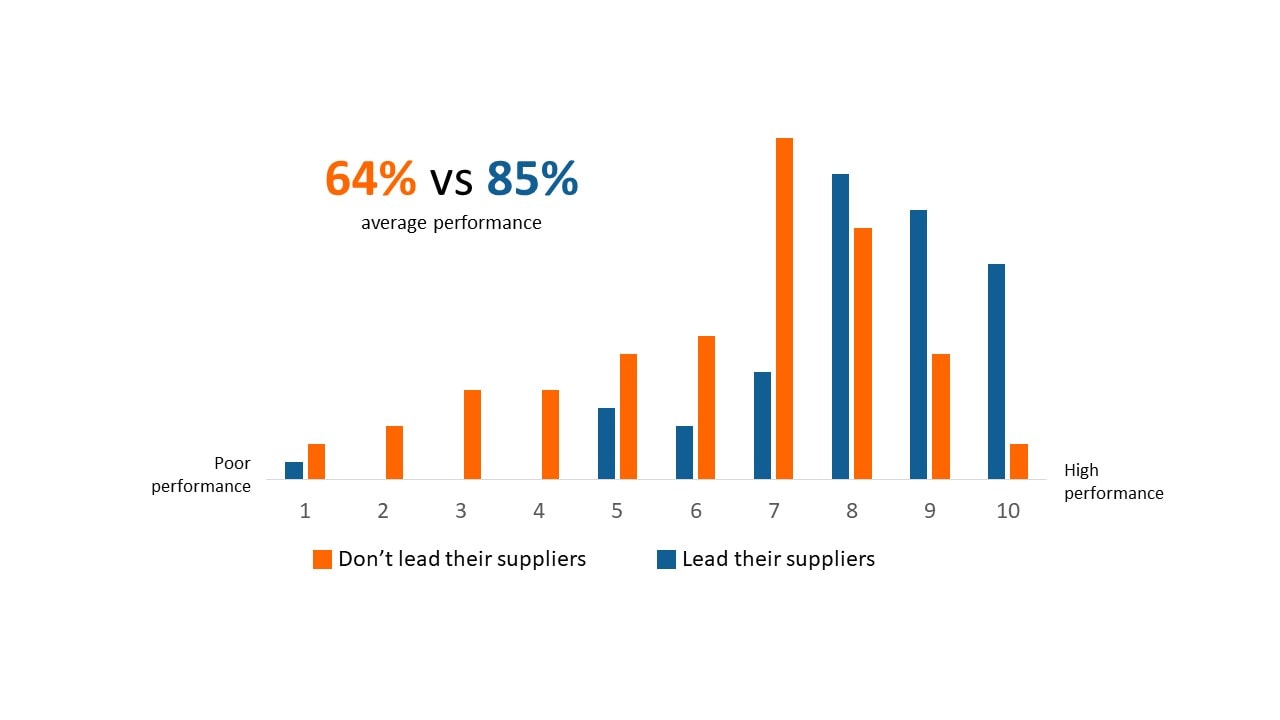

Above is a representation of gauged performance improvement, with companies that reign greater leadership over their suppliers, versus those who do not lead their suppliers. Companies that do lead suppliers yield greater performance improvements.

This is a result in operating in a modern economy, where we mainly produce and buy services, not goods. Making suppliers’ staff, not machines or production lines, the key to success.

The formula to achieving this high performance is not simple management, but leadership. Specifically, this means that successful procurement teams have found ways to:

- Understand the supplier’s strengths and build on them: Understand where weaknesses lie, avoid or mitigate, and build on strengths to increase performance.

- Seek the supplier’s input and experience when solving business problems: The chances are your suppliers have seen it all, seek their advice and input into problems your business might be facing.

- Express confidence that goals will be achieved: Positivity and optimism are far better motivators for staff and suppliers, than negativity and cynicism.

- Punishment does not lift performance: Written, contractual punishments do not lift performance of suppliers, it simply places mindsets at a bare minimum standard. Inclusion of benefits for exceptional performance will see an increase in responsiveness and motivate suppliers.

If you want to ensure that you are getting the best performance from your suppliers, you must ensure that you lead them the same way you’d lead your staff. Motivate, incentivise, be positive and consult with your suppliers to better manage expectations and increase performance.

This is the first of a series of articles that focus on what can be translated from the world of managing and leading staff to the world of leading suppliers. Read on to explore:

- Five challenges we must address when ‘hiring’ our suppliers

- Contract management: seven challenges to better practice

Or download our ebook summarising the content of all articles below.